Snapshot

Emergency Power Corporation (EPC) has designed and installed backup power systems in the Midwest for over 30 years.

Some of the largest companies in the region rely on EPC for emergency power backup. These include utilities, power line companies, and a top telecom provider. They depend on EPC to keep their operations running in critical situations. And, EPC depends on C&D Technologies to keep those customers satisfied.

“C&D is specified in many of our projects. It is a combination of proven technologies backed by a century-long history of performance, and a strong overall product line that makes C&D a choice for us and our customers,” says Mike Mares, President, EPC.

Case Study Facts

Partner: Emergency Power Corp. (EPC)

Application: Emergency backup power for telecom and utility companies.

C&D Solution:

Flooded lead acid (VLA) batteries and sealed VRLA batteries

C&D Advantage:

EPC, founded by Mike Mares and Brad Marx over 25 years ago, is a Certified Partner of C&D Technologies. They have been integrating C&D batteries into emergency power backup systems since the early 1990s.

The impacts of innovation and transparency

Most impressive to owner Mike Mares has been how C&D keeps improving its technologies and power solutions. The stationary battery manufacturer is constantly developing new ideas to meet the changing needs of the telecom and utilities markets. A benefit is that many EPC customers can see those technologies firsthand.

"One great advantage is that we can bring our customers to the C&D factory in Attica, Indiana, and do a walkthrough. They see the whole manufacturing process, the technology being developed, and how that technology is being used. It gives the customer confidence in C&D and the batteries,” explained Mike.

“They realize the products for their project have not been sitting on a shelf. They leave knowing their battery is made to order. We feel this is a great selling point. We feel having a reliable, proven battery like C&D that we can trust when designing a system is important for ‘Team EPC,’ especially given some of the systems’ requirements.”

Challenges and solutions

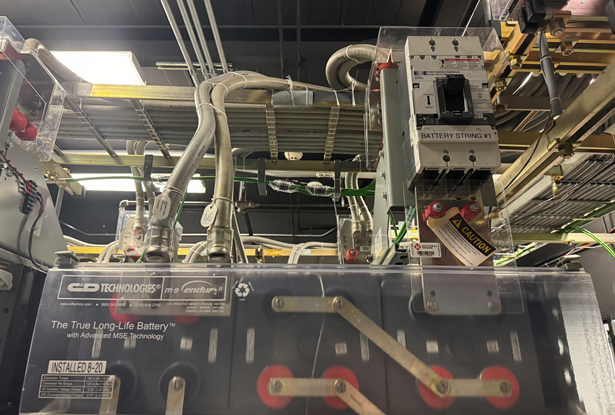

Mike and his team designed an uninterruptible power supply (UPS) and battery power room for a national telecom provider. For this facility, the chief engineer provided a floor plan and left the rest to EPC. Mike and fellow EPC engineer Don Gauvreau knew the facility load was 1300 Amps. The customer wanted 4-6 hours of backup power.

A review of the floor plan and room for the UPS battery backup revealed some challenges. The main issue was the risk of voltage drops. The EPC team needed to properly calculate those drops to ensure consistent voltage and maintain the load for the designated time frame.

"There are a lot of steps to building a backup power system," said Mike. "In this project, we had to make sure of the cabling and the number of batteries given the location of the room where the UPS system would be housed and the longevity of the load requirements. We had to engineer enough batteries to carry the load in the worst-case scenario."

The proven performance and high quality of C&D flooded lead acid batteries made the choice simple. Mike’s team was confident that the AT-39P 2180Ah system of five strings would meet the customer’s requirements with an N+1 string.

Looking forward to the next 30 years of partnership

That confidence was well-founded. There have been no issues with the system since the successful install. In EPC's experience, that is common for backup systems with C&D batteries installed.

“I know I won’t be getting a call from my customers because they have C&D batteries for their backup systems,” said Mike. “We know the batteries are going to do exactly what they are designed to do.

“C&D is a reliable source and has proven themselves time and time again over the 30 years we have had the privilege of working with them. I know that the batteries we have installed recently will be in place for the next 20 years.”