Advanced technologies

As the energy needs of our customers evolve, so do C&D batteries.

Our engineers work to continually improve and enhance product performance.

At C&D, our dedicated engineers draw from over 200 years of collective experience to develop cutting-edge products tailored to your needs. By working closely with our partners and end users, we gain deep insights into their requirements, allowing us to develop innovative solutions that are perfectly suited to their applications.

Pure Lead with MSE Technology

Using pure lead where it matters the most

The most common Pure Lead approach in the market is called TPPL for Thin Plate Pure Lead. TPPL only focuses on reducing grid corrosion. C&D’s approach focuses on improving both grid and paste. Our MSE paste combines innovative manufacturing processes with strategic use of pure lead to reduce paste dry out and improve its life by over 40%.

In addition to the paste benefits, our grids are optimized to increase the battery’s lifespan. Thanks to a patented blend of lead and alloys, our grids match other approaches, like TPPL, in reducing corrosion while offering a more rigid structure to ensure a more efficient power delivery and reduce grid shorts. Some of the key benefits of Pure Lead technology include:

Longer battery life

Up to 24-month shelf life

High-temperature stability

Lower total cost of ownership

MSE Pure Lead Plus Technology is a standard feature in msEndurII, Liberty MSE, TEL-HT High Temp, and Pure Lead Plus product families.

Most “pure lead” batteries in the market offer a pure lead, high purity grid (called thin plate pure lead or TPPL). Pure Lead Plus with MSE Technology uses both ultra-high purity and tightly controlled active materials made from pure, virgin lead.

High-purity grids improve the battery’s resistance to corrosion by eliminating grain boundaries within the grid where corrosion can form. Pure lead active materials allow C&D to closely monitor and control the grain size and purity, reducing the side reactions that can cause corrosion in the first place.

Pure Lead Plus, with MSE Technology, uses a proprietary Ball Mill Oxide made with ultra-high purity positive and negative active materials and specialized processing techniques to create a better-balanced cell. Similar to a flooded cell, this cell operates with a reduced float current. This slows grid corrosion and limits water loss typically associated with traditional VRLA batteries.

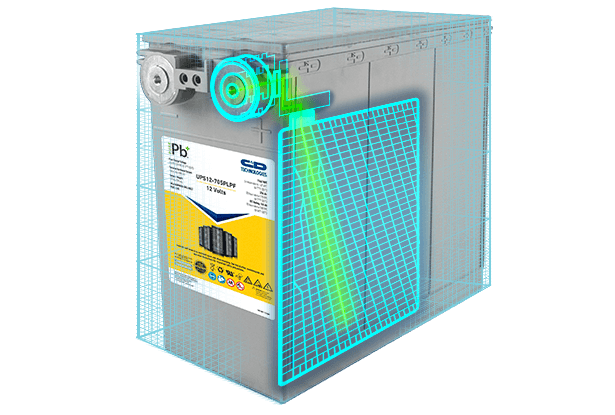

C&D Ohmic Ring™

Maintenance made easy

The C&D Ohmic Ring™ is a design feature of C&D Technologies’ VRLA battery terminals that gives battery maintenance technicians an easily accessible location to take voltage, conductance, resistance, impedance and connection resistance measurements without the need to remove connectors. This improved access helps speed up the process of taking these measurements, saving valuable time and money each quarter by allowing technicians to test more batteries regularly.

Cost savings due to easier & faster maintenance

Consistent measurements to improve system reliability

The C&D Ohmic Ring™ is a standard feature on all True Front Access™ monoblocs and msEndurII cells.

Battery maintenance plays a vital role in the reliability of any Stationary Reserve Power system. Completing this maintenance is often costly, and the value of the data collected highly depends on how the measurements were taken. In many cases, the data collected is not reliable.

The C&D Ohmic Ring™ helps solve both of these problems by speeding up battery maintenance and improving the consistency and quality of the maintenance measurements.

When taking conductance, resistance, or impedance measurements, the probe location is critical to collecting usable data. Measuring a connector, cable lug, washer or bracket can significantly change the result of that measurement.

In lab testing, taking an Ohmic measurement from a bolt changed the measurement by an average of 60% versus taking it directly from the post. Taking a reading from a connector changed the measurement by an average of 10%. This variability makes trending quarterly measurements very difficult and reduces the value of the data.

The C&D Ohmic Ring™ offers technicians a consistent location to measure directly from the post, making data more reliable and allowing customers to identify potential issues sooner.

C&D True Front Access™

Is your battery REALLY front access?

C&D True Front Access™ products feature a patented Extrusion Fusion Weld technology that allows a direct weld from the battery plates to the front access terminal of each monobloc. This weld eliminates connectors and secondary welds while allowing the post to be molded directly into the case, eliminating secondary terminal sealing processes that can be inconsistent. Eliminating secondary welds and connectors means that C&D True Front Access terminals offer lower resistance than other products, improving discharge capability and efficiency.

The only battery on the market with a direct weld front terminal

Unmatched accessibility to the terminal at the top, side, or bottom of each post

Safer maintenance

Over-sized terminals for faster maintenance and cooling

C&D True Front Access™ terminals are available across many C&D product lines including TEL Long Duration, TEL High Temperature, UPS High Rate Max, UPS Pure Lead Plus and Advanced Energy Storage (AES) models.

Introduced into stationary battery applications over 30 years ago, VRLA batteries offer customers improved energy density and footprint savings. Monoblocs have further enhanced these footprint savings, and because of their widespread use, the space required to store these battery systems has been significantly reduced.

One of the key factors contributing to these footprint savings was the development of monobloc batteries with terminals. These terminals are more easily accessible from the front of a rack or cabinet. This design has significantly reduced maintenance space between shelves in battery racks and improved technician safety by eliminating the need to reach over battery terminals to access connectors at the back of a shelf.

C&D Technologies has taken this innovation further with its True Front Access ™ designs for Telecom and UPS applications. Other designs on the market rely on more traditional manufacturing techniques, placing the terminals through the top cover of the monobloc near the front of the battery. These more conventional designs only offer side or front access to the posts, often requiring specialized connectors or cables to access them, making maintenance much more difficult.

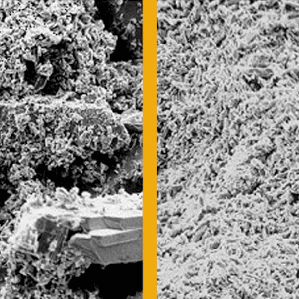

Nano-Carbon Technology

Enhanced for a longer life

C&D’s Nano-Carbon VRLA products use a high surface area nano-carbon blended specifically for C&D to enhance negative active material. Nano-scale additives provide up to 100x more nucleation sites for the formation of lead-sulfate during a discharge, allowing the negative plate active material to be maintained and recovered, even after a deep discharge. Because C&D blends our own active material, we can introduce other proprietary additives to aid in high-temperature stability and maintain the surface area of the plates. This high-tech recipe means that our nano-carbon battery models maintain predictable, reliable capacity even after years in service and thousands of cycles.

Superior cycle life in renewable energy and other frequent cycle applications

Partial State-of-Charge (PSoC) operation

More than 3000 cycles at 50% DoD

Increased recharge efficiency

Decreased grid corrosion

More than 5000 cycles from 80-50% SoC

AES Nano-Carbon Technology is specific to the AES product line.

While lead-acid batteries are standard in frequent cycle applications, they are not well suited for conditions where reliable power sources are unavailable. Traditional lead-acid type batteries in these applications suffer from one major drawback—they must be fully recharged after every cycle. When they are not brought back to a full state of charge following each cycle, sulfation of the negative plate leads to the premature failure of the cell. In renewable energy applications where power is not available under certain conditions, a generator or grid power must be used to recharge the battery system.

C&D’s lead-acid batteries operate as efficiently and safely as traditional lead-acid batteries, with the added ability to operate in Partial State-of-Charge (PSoC). Carbon in our batteries’ negative electrodes helps stabilize and prevent the damage caused by not reaching a full state of charge in traditional lead-acid designs. This allows users to charge only when power is available without fear of reducing battery life.

Operating in a PSoC means that the battery recharge can be stopped before it becomes inefficient at the 90% state of charge. Eliminating this inefficient portion of the recharge reduces the amount of power lost to heat generation and significantly reduces the amount of corrosion generated on the grid. These upgrades increase the reliability of the battery as it reaches later stages of life.

Built on C&D’s field-proven DCS Technology, nano-carbon products can stand up to repeated daily discharges and even operate in PSoC. These batteries allow users to operate their systems at peak efficiency, eliminating wasted energy due to inefficient battery charging. By operating within this ideal window, battery life is also extended.

Pure Lead AGM Battery Solutions

Pure Lead Max and Pure Lead Plus save costs, support sustainability initiatives, and can reduce your UPS system footprint by up to 28%. Learn about our Pure Lead AGM batteries for your data center battery backup.